|

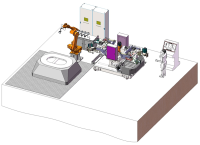

龙门式低压铸造机

收藏

·用途:铜合金、锌合金产品铸造。 ·主要结构:主机,炉子、接料车、石墨槽、洗模室、葫芦吊和控制系统、液压系统、浇注系统、气动系统组成。 ·控制系统采用西门子PLC控制,机械手横移采用伺服驱动,速度快、性能稳定、控制精度高。 ·炉子容量18T,熔化率350KGH,无级调功调压,各感应体线圈、水套冷却水有流量、水压检测。 ·接料车:具有前后、上下、翻转功能,能直接将产品送到储物周转车。 ·洗模室:模具氧化物多时可自动将模具移至洗模仓内清理。 ·电动葫芦:有效起吊500KG,主要用于清炉时炉盖起吊。 ·石墨槽:有恒温、石墨搅拌功能。 ·液压系统采用国际知名品牌组合,主要有SUN、REXROTH、YUKEN等,性能稳定,抗污性强,适合水性液压油运行的专用元件。 ·炉子浇注系统:采用NORGREN、FESTO等品牌气动元件组成,压力比例控制,并双安全阀保护,确保浇注品质和安全。 ·由中文显示触控面板设定各项功能及参数,操作容易井具有故障码显示功能便于检修。 ·Applicaion: Casting of copperlly & zinc lloy products. ·Main structure: The main engine is composed of furnace, feeder machine, graphite cuvette, mold washing chamber, chain block and control system, hydraulic system, casting system and pneumatic system. ·Control system adopts Siemens PLC contoller, mechanical hand sideway adopts servo driver, and is fast,stable in performance and highly -accurate in control. ·Fumace capecity 18T, melting rate 350kg/h, jacket- cooling water and press re testing availble for nonpoler power and pressure adjusting, every inductor coil. ·Feeder machine: Front and back, up and down swinging function available, be able to send the products to the storing cart ·Mould washing chamber: The mould can be automatic sent to the mould washing chamber for cleaning in case of too much oxide on the mould. ·Electric chain block: Effective lifing 500kg, mainly used for the furmace ifig while fumace cleaning. ·Graphite cuvette: Constant temperature and graphite mixing function available. ·Hydrau dic system adopts the intermational femous brand composition SL JN, REXROTH, YUKEN and so on,with stable performance, strong pollution resistance, suitable for the special water-based hydralic ail operation components ·Furnace casting system: Adopts the brand pneumatic components like NORGREN,FESTO, proportion pressure control, and the protection of dou ible safety valves, ensures the casting qulty and the safety.

产品用途:本机可用于锌合金与铜合金的各种小部件的铸造,因为使用低压铸造工艺大大的减少了产品的内部气孔,提高了产品质量。因此低压铸造机受到了广大厂商的欢迎。案例展示:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||